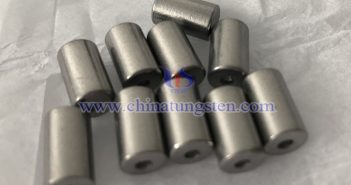

Barium tungsten electrode is a material widely used in electron tube cathodes, and is valued for its good emission performance and stability. The manufacturing process of barium tungsten electrode is mainly based on the impregnation method, which can effectively avoid the problems of barium volatilization and uneven distribution that may be caused by direct mixed sintering. It is a relatively mature and commonly used process. The preparation of barium tungsten electrode usually includes the following main steps: 1. Preparation of…