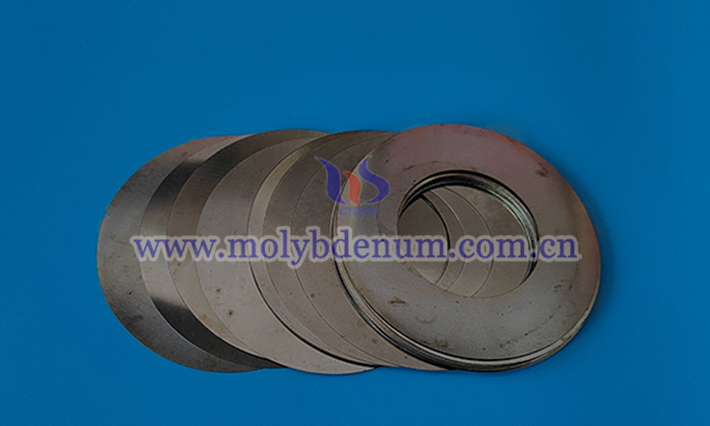

Molybdenum sheet is a thin material processed from molybdenum metal, typically ranging from 0.01 to 2 millimeters in thickness. Due to its excellent high-temperature performance, corrosion resistance, and superior mechanical properties, it is widely used in electronics, aerospace, high-temperature furnaces, and chemical industries. Molybdenum sheet can be manufactured in rectangular, circular, or custom shapes, with widths ranging from 10 to 1,000 millimeters and lengths up to 2,000 millimeters or cut to specific requirements.

Molybdenum sheet has a density of 10.28 g/cm3, a high melting point, a low thermal expansion coefficient, high tensile strength, good ductility, and excellent creep resistance. At room temperature, it resists corrosion from dilute acids (e.g., hydrochloric acid) and alkalis, outperforming iron.

The manufacturing of molybdenum sheet primarily involves two processes: powder metallurgy and rolling. The powder metallurgy method starts with high-purity molybdenum powder, which is pressed into a green compact under high pressure and then sintered at approximately 2,000°C in a vacuum or hydrogen atmosphere to achieve 90-95% of theoretical density. This is followed by hot forging or hot rolling to further densify the material, cold rolling to a thickness of 0.01-1 millimeter, annealing to relieve internal stresses, and polishing or acid pickling to meet surface finish standards. The rolling process includes hot rolling and cold rolling. During production, techniques such as spectral analysis, mechanical testing, microscopic examination, and surface testing ensure precise specifications and reliable performance.

The outstanding properties of molybdenum sheet make it highly valuable across various fields. In the electronics industry, it is used as a sputtering target for depositing thin films, a substrate for thermal matching with silicon, or a lead frame, requiring high purity and excellent flatness. In high-temperature furnaces, molybdenum sheet serves as a reflective screen, heating element, and connector, leveraging its high melting point and thermal conductivity. In sapphire crystal growth furnaces, molybdenum sheet covers and reflective screens protect the crystal growth process due to their thermal expansion compatibility.