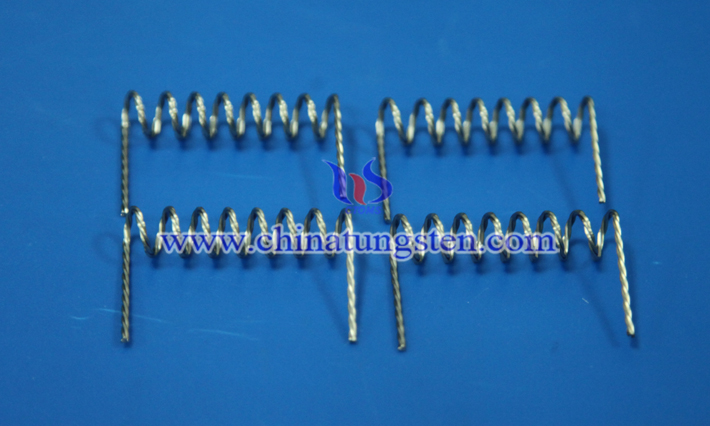

?As a typical representative of refractory tungsten products, tungsten heater is deep-processed products made from pure tungsten wire or doped tungsten wire. Known as "tungsten heater" in English, they generally contain over 99.95% tungsten and have diameters ranging from ?0.2–1.2 mm?.

?Physicochemical Properties?

Tungsten heater exhibits the following characteristics:

High melting point, high density, high strength, and high hardness. Large electrical resistivity, low vapor pressure, and low evaporation rate. Small thermal expansion coefficient, excellent high-temperature resistance, wear resistance, impact resistance, and corrosion resistance. Good electrical and thermal conductivity.

?Note?: Heaters made from ?doped tungsten wire? (e.g., potassium-, silicon-, and aluminum-doped tungsten) demonstrate superior overall performance compared to those made from pure tungsten wire, particularly in terms of reduced brittleness and improved processability.

?Production Process?

The manufacturing workflow for tungsten heater includes:

?Calcination?: Ammonium paratungstate (APT) is roasted to produce blue tungsten oxide (BTO).

?Doping?: BTO is blended with dopants (e.g., K?O, SiO?, Al?O?) to create doped blue tungsten oxide.

?Reduction?: The doped oxide is reduced to doped tungsten powder.

?Forming and Processing?: The powder undergoes pressing, sintering, rotary forging, annealing, wire drawing, and filament firing.

?Applications?

Tungsten heater is widely used as ?evaporation sources in vacuum coating machines? for depositing thin films in industries such as:

Computers, cathode-ray tubes (CRTs), mirrors, and plastics.

Automotive headlights, smartphone casings, precision optics, decorative glass, cosmetic packaging, and photovoltaic (PV) coating products.

?Additional Information?

?Doped Tungsten Wire?: Also known as ?218 tungsten wire? or ?non-sag tungsten wire?, it incorporates trace amounts of potassium oxide (K?O), silicon oxide (SiO?), and aluminum oxide (Al?O?) during production to enhance performance.