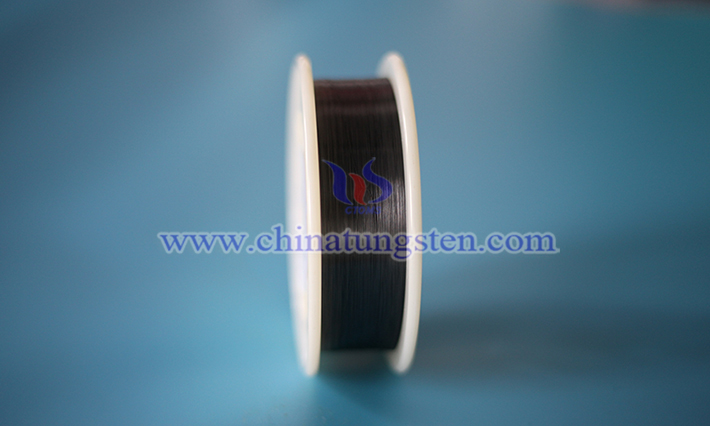

The applications of cutting-resistant tungsten wire in the semiconductor field primarily benefit from its high strength, wear resistance, fineness, and excellent performance in precision machining. Its uses are mainly concentrated in areas such as wafer preparation, precision machining, and packaging testing.

1. Wafer Cutting

Cutting-resistant tungsten wire is widely used as a cutting material in wire saws to slice silicon ingots into thin wafers. The high hardness and wear resistance of tungsten wire enable it to withstand prolonged cutting processes while maintaining exceptional precision and minimizing material loss. This technique is particularly critical in producing foundational materials for integrated circuits (ICs) and photovoltaic solar cells.

2. Precision Component Machining

In the production of components for semiconductor manufacturing equipment, cutting-resistant tungsten wire is utilized to cut or shape small and complex structures. For instance, when manufacturing key parts of lithography machines or deposition equipment, the wire’s fineness and high-temperature resistance ensure processing quality and stability.

3. Electrode Material

Due to its excellent electrical conductivity and corrosion resistance, tungsten wire is sometimes employed as an electrode or auxiliary material in semiconductor processing. For example, in certain plasma etching or electrical discharge machining (EDM) processes, cutting-resistant tungsten wire serves as an electrode wire to precisely remove material.

4. Packaging and Testing

During the packaging of semiconductor chips, cutting-resistant tungsten wire can be used to cut packaging materials or trim lead frames. Its high strength and fracture resistance ensure stability and consistency during high-speed operations. Additionally, in chip testing, tungsten wire is sometimes a component of probe materials due to its wear resistance and reliability.

5. MEMS (Microelectromechanical Systems) Manufacturing

In the production of microelectromechanical systems (MEMS), cutting-resistant tungsten wire is used to cut or process the substrates of miniature sensors and actuators. The wire’s precision and durability make it suitable for manufacturing these micron-scale structures.