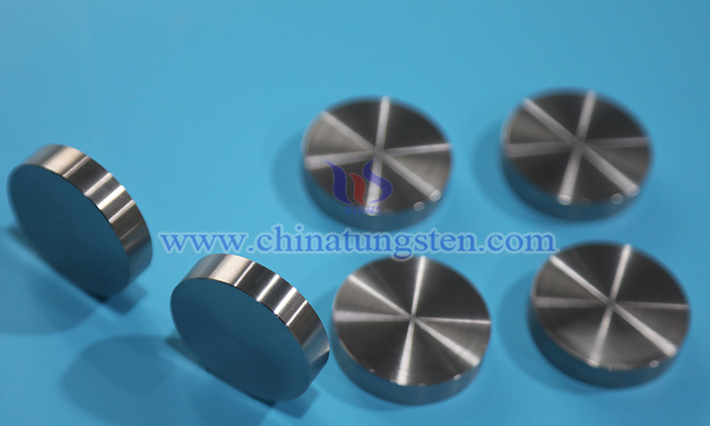

Tungsten is the core component of tungsten-nickel-iron alloy, imparting exceptional counterweight performance through its high density of 19.35 g/cm3. It also enhances the alloy’s strength and hardness via solid-solution strengthening and particle dispersion strengthening, while optimizing its radiation absorption capacity, making it an ideal choice for high-performance shielding materials.

The tungsten content (approximately 90%–98%) significantly impacts alloy properties. Higher tungsten levels generally increase density; for instance, a 90W-7Ni-3Fe alloy has a density of about 17.1 g/cm3, a 93W-4Ni-3Fe alloy around 17.6 g/cm3, and a 97W-2Ni-1Fe alloy approximately 18.5 g/cm3. This density advantage is crucial for applications in counterweights and shielding.

In terms of mechanical properties, tungsten content is positively correlated with strength. As tungsten increases from 90% to 97%, tensile strength rises from 900–1,000 MPa to 920–1,100 MPa, and hardness increases from 24–28 HRC to 28–36 HRC. This strengthening effect stems from tungsten particles reinforcing the matrix, though excessive tungsten increases brittleness. Experimental data shows that a 97W-2Ni-1Fe alloy has an elongation of 6%–13%, lower than the 18%–29% of a 90W-7Ni-3Fe alloy, indicating a trade-off in ductility at higher tungsten levels.

Tungsten content also affects processability. High-tungsten alloys, with their increased hardness and brittleness, are prone to cracking during cutting or stamping. Lower-tungsten alloys, however, offer better ductility and weldability, making them suitable for complex-shaped parts.

In radiation shielding, tungsten’s high density provides superior absorption compared to lead at the same thickness, with the added benefits of being non-radioactive and environmentally friendly, ideal for medical and nuclear industries. However, excessive tungsten can reduce toughness and impact resistance, necessitating optimized composition ratios based on specific applications. Additionally, tungsten content influences the alloy’s thermal properties to some extent.