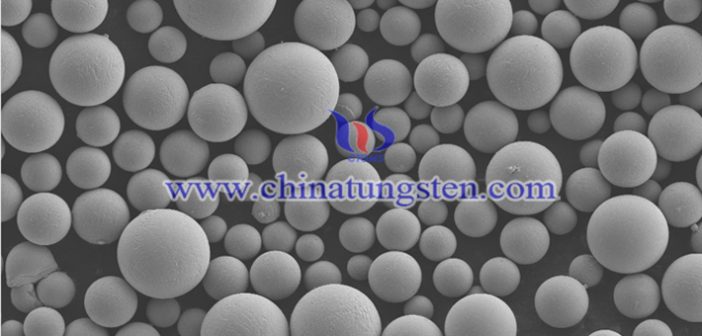

As an important raw material for tungsten production, the physical and chemical properties of spherical tungsten powder (W) directly affect the quality and use of tungsten products. Under normal circumstances, the higher the purity of the powder, the lower the oxygen and carbon content, the better the thermodynamic properties of tungsten processing materials. However, the physical and chemical properties of the powder are not the only factor that determines the quality of tungsten products. The performance of tungsten parts is also restricted by the production process. Compared with the traditional powder metallurgy method, 3D printing technology is more suitable for manufacturing tungsten parts for the following reasons:

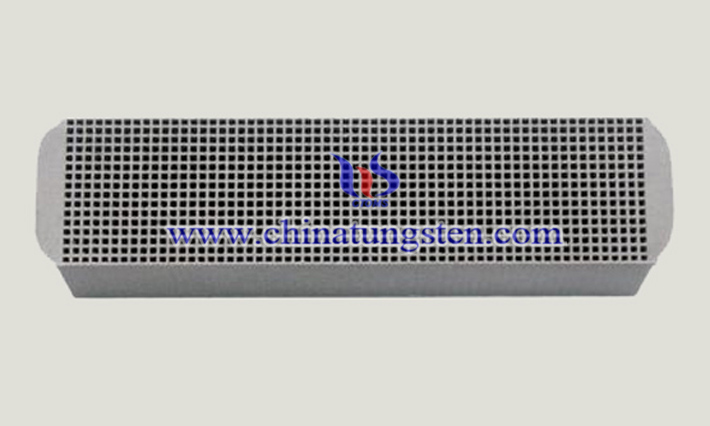

Powder metallurgy is a process technology that uses metal powder as a raw material to produce various shapes of products after forming and sintering. The advantages are: 1) Special materials can be processed; 2) Material utilization rate is high; 3) Mass production is possible; 4) Material distribution accuracy is high. The disadvantages are: 1) Poor product strength and toughness; 2) Can not be made into large products; 3) Can only prepare some simple structure parts; 4) High cost of compression mold.

Powder metallurgy is a process technology that uses metal powder as a raw material to produce various shapes of products after forming and sintering. The advantages are: 1) Special materials can be processed; 2) Material utilization rate is high; 3) Mass production is possible; 4) Material distribution accuracy is high. The disadvantages are: 1) Poor product strength and toughness; 2) Can not be made into large products; 3) Can only prepare some simple structure parts; 4) High cost of compression mold.

3D printing technology, also known as additive manufacturing, is a technology that uses metal powder and other bondable materials to produce parts by layer-by-layer printing based on digital model files. The advantages are: 1) Strong production capacity, mainly reflected in simple operation and high portability of 3D printers; 2) Complicated parts that cannot be produced by powder metallurgy can be manufactured; 3) Low production cost and short production cycle; 4) The precision is high, and the comprehensive performance is superior to the products made by powder metallurgy; 5) Green and environmental protection, with few by-products in the whole process. The disadvantages are: 1) High performance requirements for metal powder; 2) If the operation is improper, the product will also have micro-cracks.